American Airlines.

This past week I was sent out to Fort Worth, Texas for work to set up a children's exhibit at the C.R Smith Museum. The museum featured a permanent collection of airplanes, historical wardrobes, relics and most recently our museum's Tinkertoy exhibit.

I won't bore those of you that are familiar with my line of work, so instead ill show you all the fascinating machinery that I saw while I was there.

This museum had actual jet turbines that were opened up so that the public could see all the compression turbines that make a jet turbine so efficient. The Caption in front of the turbine reads:

"Pratt & Whitney JT-3D Engine

The Pratt & Whitney JT-3 engine powered American Airlines' first jetliner, the Boeing 707

The first JT-3 engines produced eleven thousand pounds of thrust

for take off. This was barely adequate, and early 707s sometimes had to make

long rolls down the runway before reaching high enough speeds to take off. To

overcome this problem, engineers at Pratt & Whitney devised a system for

injecting water into the engine’s intake during take off. This reduced the

engine temperature, increased the density of its exhaust and increased the

engine’s thrust to 13,500 pounds.

Later models, like the JT-3D shown here, did not have the

water injection system. They had a large fan housed in a duct mounted near the

engine’s front. The fan operated much like a propeller and increased the engine’s

thrust. The last model of the JT-3D produced by Pratt & Whitney had a

maximum thrust of 19,000 pounds.

American Airlines operated the Boeing 707s, with their JT-3

engines, until 1981."

Just look at all those compression fins.

(I claim no ownership of the following passage but find it absolutely fascinating so I would like to share it with you. I highly suggest if you are ever in Fort Worth, Texas that you check out the museum for yourself!)

"Wright R3350 Engine

The Wright R-3350 weighed more than 3500 pounds. It had

eighteen cylinders and thirty-six spark plugs. At full throttle it developed

3,400 horsepower. With these powerful engines on its DC-7 Flagships, American

inaugurated the first non-stop transcontinental service in both directions in

1953. Range was one achievement-speed was another. The DC-7 could make the

transcontinental trip in less than eight hours.

The engine had an ingenious, but complicated, system to

boost engine horsepower without increasing fuel consumption. The engine’s

exhaust turned three power recovery turbines, each of which turned a fluid

coupling shaft connected to the main crankshaft. Each power recovery turbine

added 200 horsepower to the engine. This “turbo-compound” system harnessed the

energy of the engine’s exhaust, which would otherwise have been lost.

The R-3350 turbo-compound marked the final stage of piston

engine development for American Airlines aircraft. After the DC-7, the next

aircraft added to the American Airlines fleet were the turboprop Lockheed

Electra and turbojet Boeing 707"

I remarked to Tim, the head of exhibits that I was drawn to this specimen because the finned cylinders reminded me a lot of the fins on the BMW motorcycles.

Close-up look of the size of a airplane piston. It is MASSIVE in comparison to all the motorcycles I have worked on.

Close-up look of the turbocharger.

You know what they always say, if you want to go fast, you also need to be able to stop fast.

"Bendix

Wheels and Brakes

For the

McDonnell Douglas

MD-11"

I don't necessarily know what I was looking at, but all the mechanical components make my head spin.

An outside look at the brakes to the McDonnell Douglas MD-11.

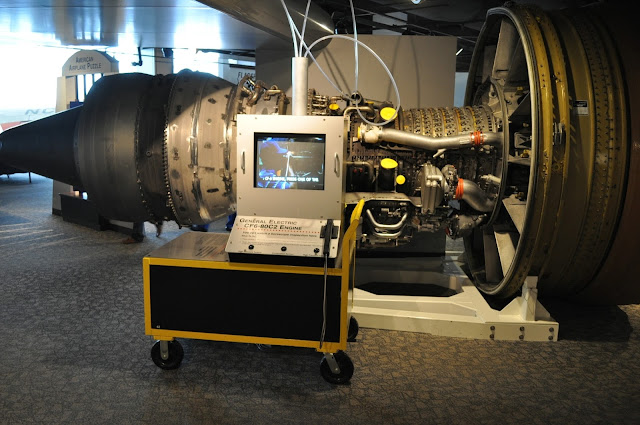

In this following exhibit, patrons were invited to use a borescope to inspect the inside of multiple passageways in this engine. Fascinating!

The monitor played pre recorded videos of the views inside multiple passageways.

Overlooking the highway was this massive plan in the hanger. If only the Betty Brinn had this sort of real estate!

The following photos I took because they made me think about my industrial processes class, and particularly Frankie Flood who would really appreciate seeing workers using mills and lathes to machine the parts for airplanes.

Assembling.

Machining.

Turning.

Really fascinating museum, I would highly recommend you all visit it for yourself. There was so much to look at there was no way I could possibly cover everything in one blog post!

Stay tuned to check out whats next!

Comments

Post a Comment